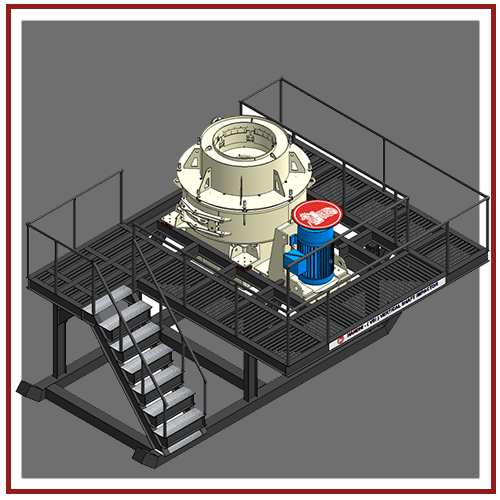

Vertical Shaft Impactor

|

Power, kW (HP) |

75 (100) |

110 (150) |

150 (200) |

187 (250) |

|

Number of drives |

1 |

1 |

1 |

1 |

|

Dry Weight,kg (lbs) |

6150 (13459) |

6200 (13600) |

6290 (13867) |

6310 (13911) |

|

Rotor diameter (mm) |

700 |

700 |

700 |

700 |

|

Recommended feed size (mm) |

<32 |

<32 |

<32 |

<32 |

|

Throughput Capacity (TPH) |

60 |

90 |

120 |

|

About VSI & Applications

The material from the feeder rotates rapidly with the movement of the rotor to obtainhigh kinetic energy, and then is transferred to the crushing section. here, kinetic energy istransformed into impact force, causing the stones to collide with each other and break.

Being a wide range operating crusher, Nandhi crusher finds its applicability in wide of area.It includes areas of small capacity mineral plants to large mining and minerals areas.

AGGREGATES AND SAND

VSI,manufactured sand made from clear granite rocks is very widely used in construction field.Highly shaped cubical sand particles are produced and seperate concrete sand plastering sand can be taken.

MINING

Very finely graded products such as mill feed,sinter feed or material for heap leach operations etc, can be produced in high quality using the Nandhi VSI.Capital saving as well as increased production is made easy.

NANDHI VSI AUTOMATION

Nandhi VSI has got a highly advanced and sophisticated automated control system.The con-trol is highly user-friendly in operation.It gives clear ‘on screen’ data of machine vibration,temperature (bearings,motor shaft),electricity consumption etc. The safety outer lock system restricts the service door Alarms are provided to inform the operation in case of any emergency or mishappening.

SPECIALTIES

- Indirect usage of wear parts for crushing and hence reduced wear.

- Constant product gradation and minimum change in shape with wear and tear of parts.

- Superior product shape and quality.

- Reduced wear and tear helps in bringing operational cost to minimum.

- Easy and fast services and replacement of spare parts and wear parts.

- Low vibration and noise ,makes the machine less pollute and eco-friendly.

- Well automated touch screen controls,alarm indicators and good monitoring of temperature,power usage,running load conditions,etc. makes it best.