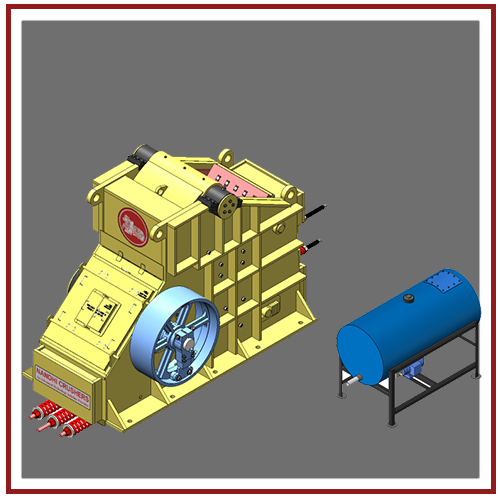

Double Toggle Primary Jaw Crusher

Nandhi Primary Crushers are of double-toggle oil lubricated type, and of very robust construction with large mouth openings to allow free flow of rock boulders to be crushed into soiling. In this type of crushers, the moving jaw is driven by the eccentric shaft that moves the front and rear toggles up and down. Each shaft revolution causes the moving jaw to close at the downstroke and openup during the upstroke. The toggle is kept in place by springloaded tension rod. A Geared pump with a separate drive unit pums will allow the oil from the voluminous tank to bearing and toggle assembly, ensure the constant positive lubrication of the system. Be side the positive lubrication system, the leverage provided by thetoggle mechanism and th e clutch system protect the bearings and main shaft from sudden overloads. and the jaw plates has longevity, incomparable with other models of jaw crushers. excelent performance and the most economical.

|

Model |

Feed Size (mm) |

Crushing Capacity (TPH) |

Power (HP) |

RPM |

Weight |

|

24" x 14" (600mm x 350mm) |

12" (300) |

50 - 60 |

50 |

325 |

6.25 Tons |

|

30" x 15" (750mm x 375mm) |

15" (400) |

60 - 70 |

50 |

325 |

8.5 Tons |

|

30" x 24" (750mm x 600mm) |

24" (600) |

75 - 150 |

60 - 75 |

325 |

14.5 Tons |

|

36" x 30" (900mm x 750mm) |

30" (750) |

100 - 200 |

100 |

300 |

24 Tons |

|

48" x 36" (1200mm x 950mm) |

36" (900) |

150 - 300 |

150 |

300 |

45 Tons |